- Stainless steel coil

- Stainless steel plate

- Stainless steel pipe

- Stainless steel rod

- Stainless steel sections

- Carbon steel coil

- Carbon steel plate

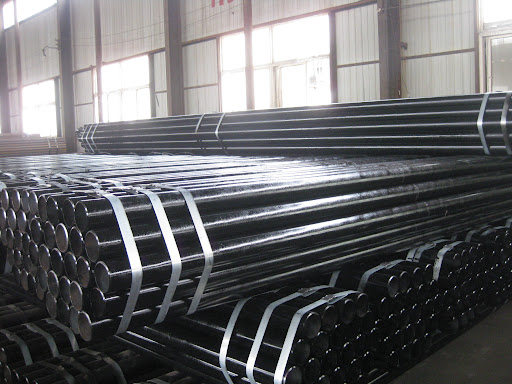

- Carbon steel pipe

- Carbon steel Profile & Section

- Galvanized steel coil

- Galvanized steel plate

- Pre-painted Galvanized Steel Coil

- Handox wear resistant steel plate

ASTM A333 (ASME S/A-333) Pipe grades permit low temperature service. This specification covers nominal (average) walled pipe almost exclusively in seamless. Several grades of ferritic steel are included. Some product sizes may not be available under this specification because heavier wall thicknesses have an adverse effect on low-temperature impact properties. A333 pipe is furnished to nine different grades designated by numbers 1, 3, 4, 6, 7, 8, 9, 10, & 11. Discussed herein are Grades 1 and 6. The seamless pipes are drawn from a single billet of the material whereas the ASTM A333 Grade 6 Welded Pipe Specification mandates it be welded from a strip or sheet of the same material grade. The form of the pipes can vary as round or hydraulic in most cases.

|

Product Name |

ASTM A333 Low Temperature Steel Pipe |

|

Dia. |

10.3-3620mm |

|

Length |

3m -12m or as required |

|

Thickness |

1.25-60mm |

|

Standard |

GB,ASTM,DIN,BS,JIS |

|

Technique |

Cold drawn / Hot rolled |

|

Surface Treatment |

3PE/3LPE, FBE, Galvanized ETC. |

|

Thickness Tolerance |

±0.01mm~ ±0.25mm |

|

Material |

ASTM A333 |

|

Application |

oil and gas, buildings, housing, and heavy equipment. |

|

MOQ |

1 ton , We can accept sample order. |

|

Shipment Time |

Within 15-20 workdays after receiving deposit or workable L/C |

|

Export Packing |

Waterproof paper, and steel strip packed. |

|

Capacity |

250,000 tons/year |

ASTM A333 Chemical Composition:

Chemical Composition of ASTM A333

Element

Grade 1, %

Grade 3, %

Grade 4, %

Grade 6, %

Grade 7, %

Grade 8, %

Grade 9, %

Grade 10, %

Grade 11, %

C

0.3

0.19

0.12

0.3

0.19

0.13

0.2

0.2

0.1

Mn

0.40–1.06

0.31–0.64

0.50–1.05

0.29–1.06

0.9

0.9

0.40–1.06

1.15–1.50

0.6

P

0.025

0.025

0.025

0.025

0.025

0.025

0.025

0.035

0.025

S

0.025

0.025

0.025

0.025

0.025

0.025

0.025

0.015

0.025

Si

...

0.18–0.37

0.08–0.37

0.10 min

0.13–0.32

0.13–0.32

...

0.10–0.35

0.35

Ni

...

3.18–3.82

0.47–0.98

0.4

2.03–2.57

8.40–9.60

1.60–2.24

0.25

35.0–37.0

Cr

...

...

0.44–1.01

0.3

...

...

...

0.15

0.5

Cu

...

...

0.40–0.75

0.4

...

...

0.75–1.25

0.15

...

Al

...

...

0.04–0.30

...

...

...

...

0.06

...

V

...

...

...

0.08

...

...

...

0.12

...

Cb

...

...

...

0.02

...

...

...

0.05

...

Mo

...

...

...

0.12

...

...

...

0.05

0.5

Co

...

...

...

...

...

...

...

...

0.5

*For Grade 6, the limit for columbium may be increased up to 0.05 % on heat analysis and 0.06 % on product analysis.

ASTM A333 Physical properties :

ASTM A333

Tensile Strength, min.

Yield Strength, min.

Elongation %, min.

Grade

psi

MPa

psi

MPa

Longitudinal

Transverse

Grade 1

55 000

380

30 000

205

35

25

Grade 3

65 000

450

35 000

240

30

20

Grade 4

60 000

415

35 000

240

30

16.5

Grade 6

60 000

415

35 000

240

30

16.5

Grade 7

65 000

450

35 000

240

30

22

Grade 8

100 000

690

75 000

515

22

...

Grade 9

63 000

435

46 000

315

28

...

Grade 10

80 000

550

65 000

450

22

...

Grade 11

65 000

450

35 000

240

18

...

| NPS | O.D | ANSI B36.10 B36.19 Wall Thickness | ||||||||||||||

| DN(mm) | inch | mm | Sch5S | Sch10S | Sch10 | Sch20 | Sch30 | Sch40S | STD | Sch40 | Sch60 | Sch80 | XS | Sch80S | Sch100 | XXS |

| 8 | 1/4 | 13.72 | - | 1.65 | - | - | - | 1.73 | 1.73 | 1.73 | - | 3.02 | 3.02 | 3.02 | - | - |

| 10 | 3/8 | 17.14 | - | 1.65 | - | - | - | 2.31 | 2.31 | 2.31 | - | 3.2 | 3.2 | 3.2 | - | - |

| 15 | 1/2 | 21.34 | 1.65 | 2.11 | - | - | - | 2.77 | 2.77 | 2.77 | - | 3.73 | 3.73 | 3.73 | - | 7.47 |

| 20 | 3/4 | 26.67 | 1.65 | 2.11 | - | - | - | 2.87 | 2.87 | 2.87 | - | 3.91 | 3.91 | 3.91 | - | 7.82 |

| 25 | 1 | 33.4 | 1.65 | 2.77 | - | - | - | 3.38 | 3.38 | 3.38 | - | 4.55 | 4.55 | 4.55 | - | 9.09 |

| 32 | 1 1/4 | 42.16 | 1.65 | 2.77 | - | - | - | 3.56 | 3.56 | 3.56 | - | 4.85 | 4.85 | 4.85 | - | 9.7 |

| 40 | 1 1/2 | 48.26 | 1.65 | 2.77 | - | - | - | 3.68 | 3.68 | 3.68 | - | 5.08 | 5.08 | 5.08 | - | 10.16 |

| 50 | 2 | 60.32 | 1.65 | 2.77 | - | - | - | 3.91 | 3.91 | 3.91 | - | 5.54 | 5.54 | 5.54 | - | 11.07 |

| 65 | 2 1/2 | 73.02 | 2.11 | 3.05 | - | - | - | 5.16 | 5.16 | 5.16 | - | 7.01 | 7.01 | 7.01 | - | 14.02 |

| 80 | 3 | 88.9 | 2.11 | 3.05 | - | - | - | 5.49 | 5.49 | 5.49 | - | 7.62 | 7.62 | 7.62 | - | 15.24 |

| 90 | 31/2 | 101.6 | 2.11 | 3.05 | - | - | - | 5.74 | 5.74 | 5.74 | - | 8.08 | 8.08 | 8.08 | - | - |

| 100 | 4 | 114.3 | 2.11 | 3.05 | - | - | - | 6.02 | 6.02 | 6.02 | - | 8.56 | 8.56 | 8.56 | - | 17.12 |

| 125 | 5 | 141.3 | 2.77 | 3.4 | - | - | - | 6.55 | 6.55 | 6.55 | - | 9.53 | 9.53 | 9.53 | - | 19.05 |

| 150 | 6 | 168.28 | 2.77 | 3.4 | - | - | - | 7.11 | 7.11 | 7.11 | - | 10.97 | 10.97 | 10.97 | - | 21.94 |

| 200 | 8 | 219.08 | 2.77 | 3.4 | - | 6.35 | 7.04 | 8.18 | 8.18 | 8.18 | 10.31 | 12.7 | 12.7 | 12.7 | 15.09 | 22.22 |

| 250 | 10 | 273.05 | 3.4 | 3.76 | - | 6.35 | 7.8 | 9.27 | 9.27 | 9.27 | 12.7 | 12.7 | 12.7 | 15.09 | 18.26 | 25.4 |

| 300 | 12 | 323.85 | 3.96 | 4.57 | - | 6.35 | 8.38 | 9.52 | 9.52 | 10.3 | 14.27 | 12.7 | 12.7 | 17.48 | 21.44 | - |

| 350 | 14 | 355.6 | 3.96 | 4.78 | 6.35 | 7.92 | 9.52 | *9.52 | 9.52 | 11.13 | 15.09 | 12.7 | 12.7 | 19.05 | 23.83 | - |

| 400 | 16 | 406.4 | 4.19 | 4.78 | 6.35 | 7.92 | 9.52 | *9.52 | 9.52 | 12.7 | 16.66 | 12.7 | 12.7 | 21.44 | 26.19 | - |

| 450 | 18 | 457.2 | 4.19 | 4.78 | 6.35 | 7.92 | 11.12 | *9.52 | 9.52 | 14.27 | 19.05 | 12.7 | 12.7 | 23.82 | 29.36 | - |

| 500 | 20 | 508 | 4.78 | 5.54 | 6.35 | 7.92 | 12.7 | *9.52 | 9.52 | 15.09 | 20.62 | 12.7 | 12.7 | 26.19 | 32.54 | - |

| 550 | 22 | 558.8 | 4.78 | 5.54 | 6.35 | 7.92 | 12.7 | *9.52 | 9.52 | - | 22.22 | 12.7 | 12.7 | 28.58 | 34.92 | - |

| 600 | 24 | 609.6 | 5.54 | 6.35 | 6.35 | 7.92 | 14.27 | *9.52 | 9.52 | 17.48 | 24.61 | 12.7 | 12.7 | 30.96 | 38.89 | - |

| 650 | 26 | 660.4 | - | *7.92 | 7.92 | 12.7 | - | *9.52 | 9.52 | - | - | 12.7 | 12.7 | - | - | - |

| 700 | 28 | 711.2 | - | *7.92 | 7.92 | 12.7 | 15.88 | *9.52 | 9.52 | - | - | 12.7 | 12.7 | - | - | - |

| 750 | 30 | 762 | 6.35 | *7.92 | 7.92 | 12.7 | 15.88 | *9.52 | 9.52 | - | - | 12.7 | 12.7 | - | - | - |

| 800 | 32 | 812 | - | *7.92 | 7.92 | 12.7 | 15.88 | *9.52 | 9.52 | 17.48 | - | 12.7 | 12.7 | - | - | - |

| 850 | 34 | 863.6 | - | *7.92 | 7.92 | 12.7 | 15.88 | *9.52 | 9.52 | 17.48 | - | 12.7 | 12.7 | - | - | - |

| 900 | 36 | 914.4 | - | *7.92 | 7.92 | 12.7 | 15.88 | *9.52 | 9.52 | 19.05 | - | 12.7 | 12.7 | - | - | - |

| 950 | 38 | 965.2 | - | *7.92 | - | - | - | *9.52 | 9.52 | - | - | 12.7 | 12.7 | - | - | - |

| 1000 | 40 | 1016 | - | *7.92 | - | - | - | *9.52 | 9.52 | - | - | 12.7 | 12.7 | - | - | - |

| 1050 | 42 | 1066.8 | - | *7.92 | - | - | - | *9.52 | 9.52 | - | - | 12.7 | 12.7 | - | - | - |

| 1100 | 44 | 1117.6 | - | *7.92 | - | - | - | *9.52 | 9.52 | - | - | 12.7 | 12.7 | - | - | - |

| 1150 | 46 | 1168.4 | - | *7.92 | - | - | - | *9.52 | 9.52 | - | - | 12.7 | 12.7 | - | - | - |

| 1200 | 48 | 1219.2 | - | *7.92 | - | - | - | *9.52 | 9.52 | - | - | 12.7 | 12.7 | - | - | - |

| 1300 | 52 | 1320.8 | - | - | - | - | - | - | 9.52 | - | - | - | 12.7 | - | - | - |

| 1350 | 54 | 1371.6 | - | - | - | - | - | - | 9.52 | - | - | - | 12.7 | - | - | - |

| 1400 | 56 | 1422.4 | - | - | - | - | - | - | 9.52 | - | - | - | 12.7 | - | - | - |

| 1500 | 60 | 1524 | - | - | - | - | - | - | 9.52 | - | - | - | 12.7 | - | - | |

| 1600 | 64 | 1625.6 | - | - | - | - | - | - | 9.52 | - | - | - | 12.7 | - | - | |

| 1700 | 68 | 1727.2 | - | - | - | - | - | - | 9.52 | - | - | - | 12.7 | - | - | |

| 1800 | 72 | 1828.8 | - | - | - | - | - | - | 9.52 | - | - | - | 12.7 | - | - | |

| 1900 | 76 | 1930.4 | - | - | - | - | - | - | 9.52 | - | - | - | 12.7 | - | - | |

| 2000 | 80 | 2032 | - | - | - | - | - | - | 9.52 | - | - | - | 12.7 | - | - | |