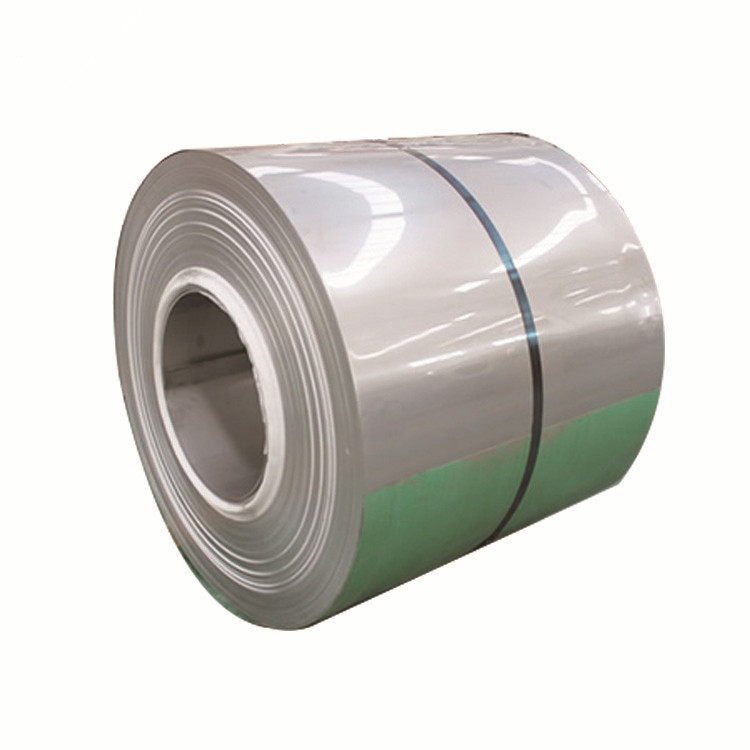

- Stainless steel coil

- Stainless steel plate

- Stainless steel pipe

- Stainless steel rod

- Stainless steel sections

- Carbon steel coil

- Carbon steel plate

- Carbon steel pipe

- Carbon steel Profile & Section

- Galvanized steel coil

- Galvanized steel plate

- Pre-painted Galvanized Steel Coil

- Handox wear resistant steel plate

Type 321 contains a titanium addition of at least five times the carbon content to overcome the sensitizing tendency during welding. Its corrosion resistance is similar to Type 304 but 321 performs better in the 800°-1650°F sensitization range. In Type 321, the oxide or carbonitride of titanium may develop minute black or dark gray inclusions. When the metal is ground or buffed these inclusions may appear and destroy surface appearance, although it will not damage the utility or workability of the metal. Resistance to abrasion is favorable.

|

Product Name |

Stainless Steel Strip Coils Grade 321 |

|

Coil weight |

3-10 ton or as required |

|

Width |

20mm-2000mm or as required |

|

Thickness |

0.1mm-3mm or as required |

|

Standard |

AISI ,AFNOR,BS |

|

Technique |

Hot rolled / cold rolled |

|

Surface Treatment |

2B, 2D, BA, NO.1, NO.4, NO.8, 8K, mirror, chequered, embossed, hairline, sand blast, Brush, etching, Hot rolled plate (HR), Cold rolled sheet (CR), SATIN (Met with Plastic Coated) etc |

|

Thickness Tolerance |

±0.01mm~ ±0.25mm |

|

Material |

321 |

|

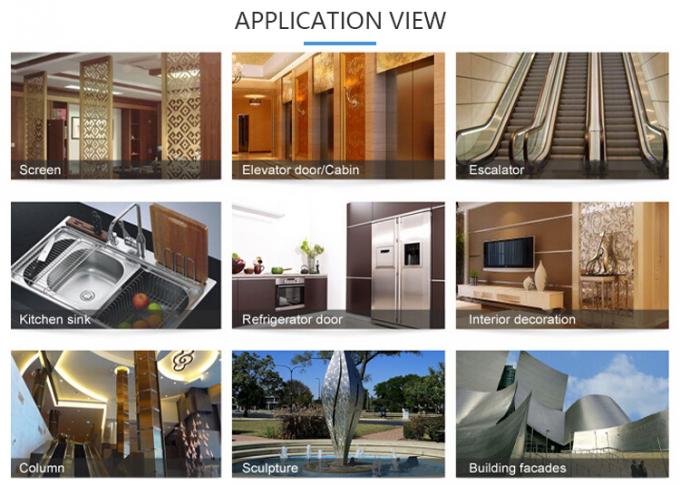

Application |

It is mainly used in the sectors of nuclear power (also in liquid sodium), reactor instrumentation, chemical apparatus (very good corrosion resistance), eg for production of acetic and nitric acid, heat exchangers, furnaces, paper and textile industries, petroleum refining and petrochemicals, grease and soap industry, food industry, dairy and fermentation plants. |

|

MOQ |

1 ton , We can accept sample order. |

|

Shipment Time |

Within 15-20 workdays after receiving deposit or workable L/C |

|

Export Packing |

Waterproof paper, and steel strip packed. |

|

Capacity |

250,000 tons/year |

Chemical Composition:

| C | Si | Mn | P | S* | Cr | Ni | Ti |

| ≤ % | ≤ % | ≤ % | ≤ % | ≤ % | % | % | ≤ % |

| 0.08 | 1,0 | 2,0 | 0,045 | 0,015 | 17,0-19,0 | 9,0-12,0 | 5 x C ≤ 0.70 |

* S ≤ 0,30 (for long term products)

S =0,015 – 0,030 ( for products to be processed)

Characteristics of 321:

| Temperature Range | Density kg/dm3 | Hardness HB 30 |

| Up to 550° C | 7.9 | ≤ 215 |

Physical property:

| Temper | Tensile Strength | Yield Strength | Elongation | Rockwell | ||

| KSi | MPa | KSi | MPa | in 2 inches % | ||

| Annealed | 75 | -515 | 30 | -205 | 40 |

B-95 max. |

FAQ:

Q1. What are your company's main products ?

A1: Our main products are stainless steel plate/sheet, coil, round/square pipe, bar, channel, etc.

Q2. How do you control quality ?

A2: Mill Test Certification is supplied with shipment, Third Party Inspection is available. and we also get ISO,SGS,Alibaba Verified.

Q3. What are the advantages of your company ?

A35: We have many professionals, technical personnel, more competitive prices and best after-dales service than other stainless steel companies.

Q4: What is the terms of packing?

A3: generally, we pack our goods in bundles or coils with rods or belts, we could also pack the goods as the customers requirement.

Q5:What is your delivery time?

A4: For stocks, we could transport the goods to loading port within 7 days after we received your deposit

For production period, it usually takes about 15 days-30 days after receiving the deposit.

Q6. Can you provide sample ?

A7: We can provide the samll samples in stock for free, as long as you contact us.

Customized samples will take about 5-7days.

Q7. How many coutries you already exported ?

A6: Exported to more than 50 countries mainly from America, Russia, UK, Kuwait, Egypt, Turkey, Jordan,India, Vietnam, Thailand, South Korea etc.