- Stainless steel coil

- Stainless steel plate

- Stainless steel pipe

- Stainless steel rod

- Stainless steel sections

- Carbon steel coil

- Carbon steel plate

- Carbon steel pipe

- Carbon steel Profile & Section

- Galvanized steel coil

- Galvanized steel plate

- Pre-painted Galvanized Steel Coil

- Handox wear resistant steel plate

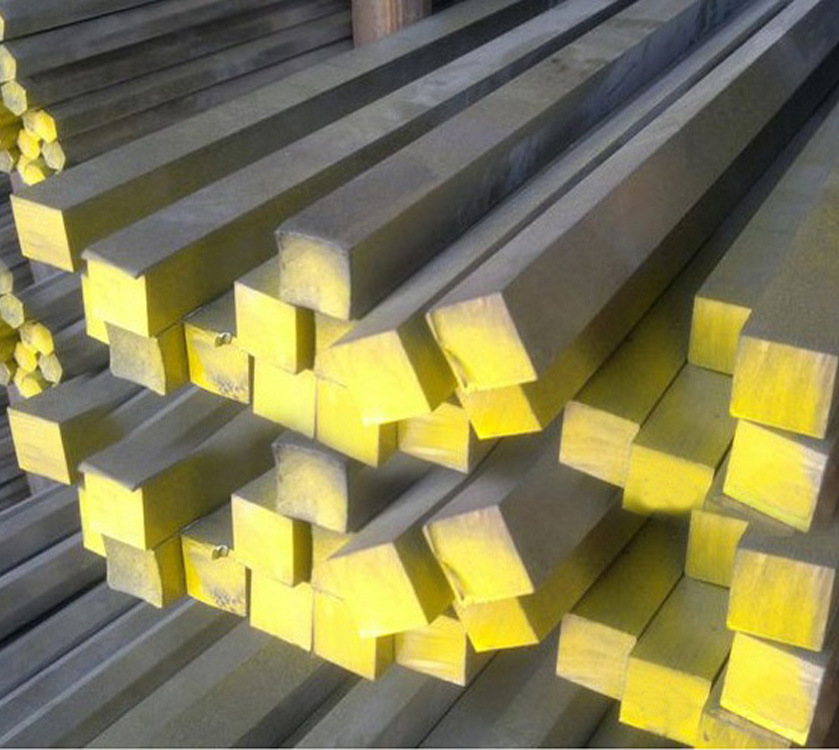

Stainless Steel Square, is the more economical stainless square bar ideal for all applications where greater strength and superior corrosion resistance is required. Stainless Square has a durable dull, mill finish that is widely used for all types of fabrication projects that are exposed to the elements - chemical, acidic, fresh water, and salt water environments.

Our supply of stainless steel square bar products come in both the cold drawn and hot rolled condition. Most of our square bar products 3″ and under is cold drawn. Cold drawn bar is shinier in appearance and has a tolerance that is similar to the hot-rolled material, which is usually slightly over-sized. Most of our square bar is supplied in lengths can be cut to size for orders.

| Product Name | Stainless Steel Square Bar |

| Size | 0.125" - 4" |

| Length | 1-12m or as required |

| Standard | ASTM/AISI ,AFNOR,BS,UNS,GB |

| Technique | Cold rolled/Hot rolled |

| Surface Treatment | non-polished finish,polished |

| Thickness Tolerance | ±0.01mm~ ±0.25mm |

| Material | SS201, SS304 /304L, SS316/316L,321 or as required |

| Application | It is mainly used in all types of fabrication projects that are exposed to the elements - chemical, acidic, fresh water, and salt water environments. |

| MOQ | 1 ton , We can accept sample order. |

| Shipment Time | Within 15-20 workdays after receiving deposit or workable L/C |

| Export Packing | Standard Export Seaworthy Package.Suit for all kinds of transport,or as required |

| Capacity | 250,000 tons/year |

Chemical Composite for Stainless Steel

|

Material |

ASTM A249 Chemical Composition % Max |

||||||||||

|

C |

Mn |

P |

S |

Si |

Cr |

Ni |

Mo |

N B |

Nb |

Ti |

|

|

TP304 |

0.08 |

2.00 |

0.045 |

0.030 |

1.00 |

18.0-20.0 |

8.0-11.0 |

^ |

^ |

^ . |

^ |

|

TP304L |

0.035 |

2.00 |

0.045 |

0.030 |

1.00 |

18.0-20.0 |

8.0-12.0 |

^ |

^ |

^ |

^ |

|

TP316 |

0.08 |

2.00 |

0.045 |

0.030 |

1.00 |

16.0-18.0 |

10.0-14.0 |

2.00-3.00 |

^ |

^ |

^ |

|

TP316L |

0.035 D |

2.00 |

0.045 |

0.030 |

1.00 |

16.0-18.0 |

10.0-15.0 |

2.00-3.00 |

^ |

^ |

^ |

|

TP321 |

0.08 |

2.00 |

0.045 |

0.030 |

1.00 |

17.0-19.0 |

9.0-12.0 |

^ |

^ |

^ |

5C -0.70 |

|

416 |

0.15 |

1.25 |

0.06 |

0.15 |

1.00 |

12.0-14.0 |

^ |

^ |

^ |

^ |

^ |

|

Material |

Heat treatment |

Temperure F (C) Min. |

Hardness |

|

|

Brinell |

Rockwell |

|||

|

TP304 |

Solution |

1900 (1040) |

192HBW/200HV |

90HRB |

|

TP304L |

Solution |

1900 (1040) |

192HBW/200HV |

90HRB |

|

TP316 |

Solution |

1900(1040) |

192HBW/200HV |

90HRB |

|

TP316L |

Solution |

1900(1040) |

192HBW/200HV |

90HRB |

|

TP321 |

Solution |

1900(1040) F |

192HBW/200HV |

90HRB |

|

TP347 |

Solution |

1900(1040) |

192HBW/200HV |

90HRB |