- Stainless steel coil

- Stainless steel plate

- Stainless steel pipe

- Stainless steel rod

- Stainless steel sections

- Carbon steel coil

- Carbon steel plate

- Carbon steel pipe

- Carbon steel Profile & Section

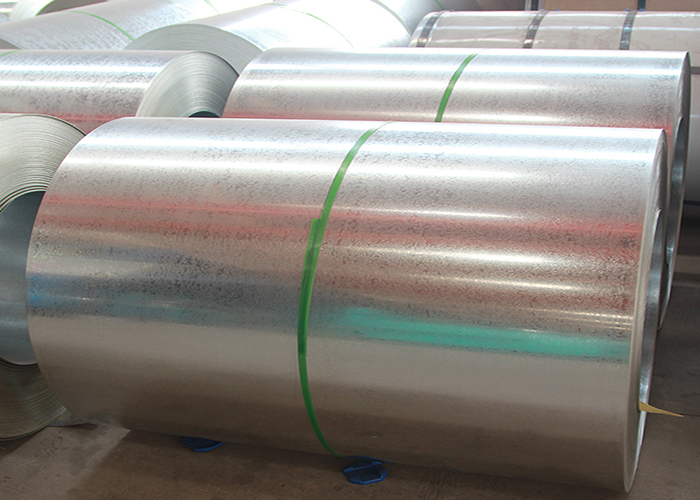

- Galvanized steel coil

- Galvanized steel plate

- Pre-painted Galvanized Steel Coil

- Handox wear resistant steel plate

Galvanized steel is defined as a carbon steel sheet coated with zinc on both sides. There are two main processes used to produce galvanized steel: continuous hot dipping and electro-galvanizing. The hot dipping process consists of passing the steel through a bath of molten zinc, while the electro-galvanizing process consists of the application of zinc through electrolytic disposition. The result is a layer of zinc tightly adhering to the base metal through an iron-zinc bonding layer.

Most important, our hot-dipped galvanized steel coil and sheet service capabilities include slitting,cutting to length, blanking, degreasing and brushing, stretcher leveling and metallurgical support.

| Product Name: | DX51D+Z Hot-dipped galvanize coil |

| Standard: | AISI, ASTM, BS, DIN, GB, JIS, DIN-1623, EN-10130, JIS-G3141, etc. |

| Material: | Q235 Q345 Welded H Beam and Hot Rolled Section Steel |

| Grade: | DX51D (SGCC,SGCD,SPCC,DX52D,DX53D are also available) |

| Coil weight: | 3-10 ton or according to your request |

| Thickness: | 0.2mm-2.5mm |

| Width: | 600mm-1250mm or according to your request |

| Zinc coating: | 60g/m² - 275g/m² |

| Technique: | hot dip galvanized |

| Performance: | durable, anti-fingerprint |

| MOQ: | 1 ton per size |

| Supply Ability: | 5000t/month |

| Delivery Time: | Within 15 days after receiving the pre-payment. |

| Export Packing: | Standard Export Seaworthy Package. |

| Payment Terms: | L/C at sight, T/T or Negotiable. |

Advantages of Galvanized Steel

The main advantage of galvanized steel is its corrosion resistance. The zinc coating serves as a barrier between the steel and the environment and will sacrifice itself in order to protect the underlying steel; Meaning the zinc will degrade much sooner than the steel itself. Additionally, it offers good processability and formability.

Galvanized Steel Coil Material Types

- Commercial Steel (CS Types A, B, and C)

- Forming Steel (FS Types A and B)

- Deep Drawing Steel (DDS Types A and C)

- Extra Deep Drawing Steel (EDDS)

- Structural Steel (SS) – further designated by Grades (33,37,40,50,80)

- High Strength Low Alloy Steel (HSLAS)

Typical Galvanized Steel Coil Applications:

- Exterior building products

- Ductwork

- HVAC products

- Flashing

- Roofing

- Doors

- Sashes

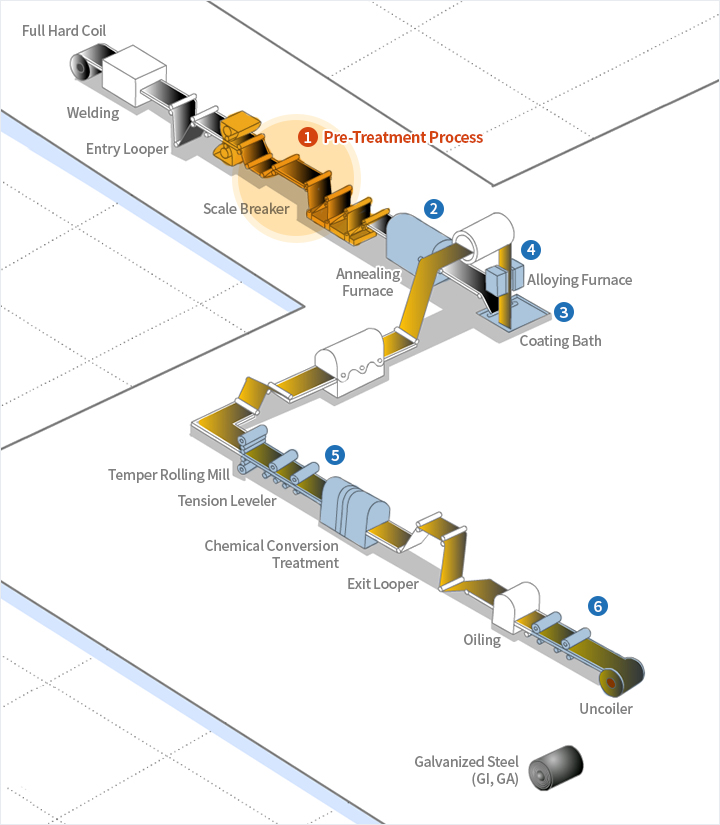

Manufacturing process: