- Stainless steel coil

- Stainless steel plate

- Stainless steel pipe

- Stainless steel rod

- Stainless steel sections

- Carbon steel coil

- Carbon steel plate

- Carbon steel pipe

- Carbon steel Profile & Section

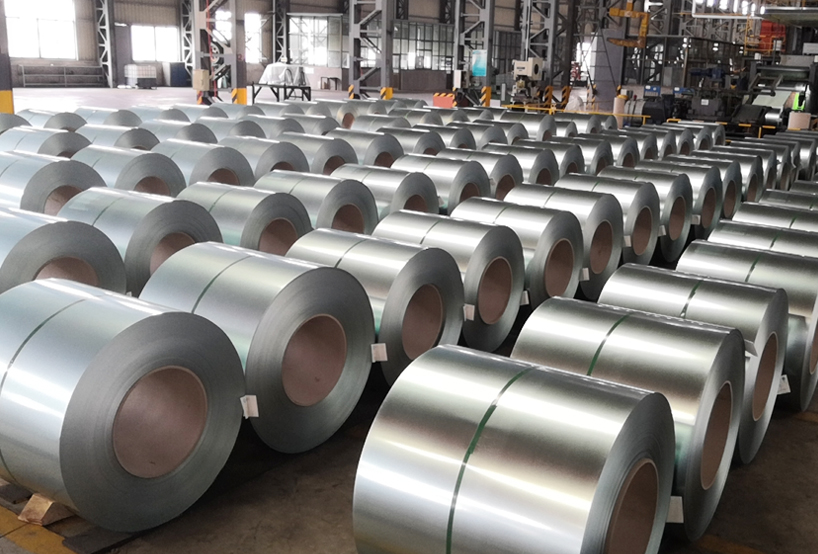

- Galvanized steel coil

- Galvanized steel plate

- Pre-painted Galvanized Steel Coil

- Handox wear resistant steel plate

Galvannealed coating (ZF) is a zinc-iron alloy coating featuring excellent resistance welding properties and paint adhesion. It is ideal coating for spot welding and high-end painting applications.

The Galvannealed coating provides first-class painted surfaces that last under demanding conditions. The surface of the Galvannealed coating is finely structured, providing an attractive appearance to the painted surface wherein the paint firmly adheres to the product. Therefore painted Galvannealed surfaces also feature excellent corrosion resistance.

Galvannealed coating can be recognized by its typically grayish, matte surface. The coating is produced by heat treatment after continuous hot-dip coating. In this heat treatment process, iron from steel reacts with zinc and forms zinc-iron compounds. The iron content of the coating is approximately 10%. Consequently, the coating provides unbeatable resistance weldability for coated steel, meaning longer electrode life and low galling on electrodes.

| Product Name: | DC51D+ZF Galvannealed coating steel coil |

| Standard: | AISI, ASTM, BS, DIN, GB, JIS, DIN-1623, EN-10130, JIS-G3141, etc. |

| Technique | Cold rolled |

| Grade: | DC51D ,DC52D,DC53D |

| Coil weight: | 3-10 ton or according to your request |

| Thickness: | 0.3mm-3.0mm |

| Width: | 20mm-1250mm or according to your request |

| Zinc coating: | 80g/m² , 100g/m²,120g/m² or according to your request |

| Surface Structure: | Zero Spangle, Regular Spangle |

| Surface Treatment: |

Galvanized |

| Brand: | Baosteel |

| Performance: | Durable, anti-fingerprint |

| MOQ: | 5 ton per size |

| Supply Ability: | 5000t/month |

| Delivery Time: | Within 15 days after receiving the pre-payment. |

| Export Packing: | Standard Export Seaworthy Package. |

| Payment Terms: | L/C at sight, T/T or Negotiable. |

Coating thickness:

| Coating designation | Minimum total coating mass,both surfaces (g/m2) * | Guidance value for coating thickness per surface, typically (μm) |

| ZF080 | 80 | 6 |

| ZF100 | 100 | 7 |

| ZF120 | 120 | 8 |

| ZF140 | 140 | 10 |

Advantages of Galvannealed coating:

| ● More attractive appearance of painted products. Best painted surface. |

| ● Longer service life of products. |

| ● Reduced welding cost. |

| ● Reduced laser cutting cost. |

| ● More fficient forming and punhing. |