- Stainless steel coil

- Stainless steel plate

- Stainless steel pipe

- Stainless steel rod

- Stainless steel sections

- Carbon steel coil

- Carbon steel plate

- Carbon steel pipe

- Carbon steel Profile & Section

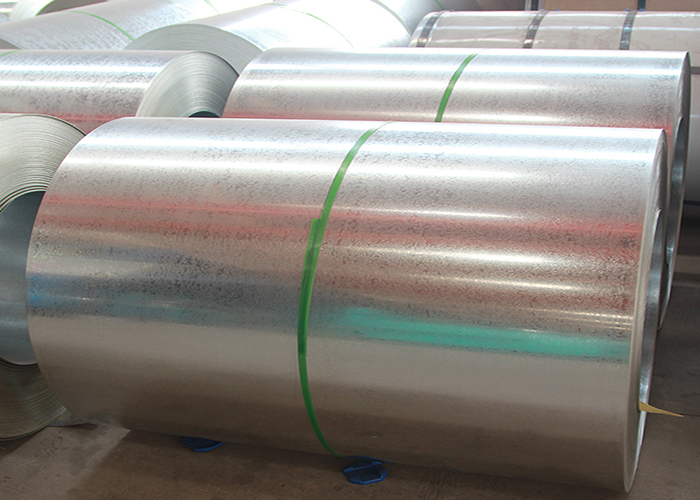

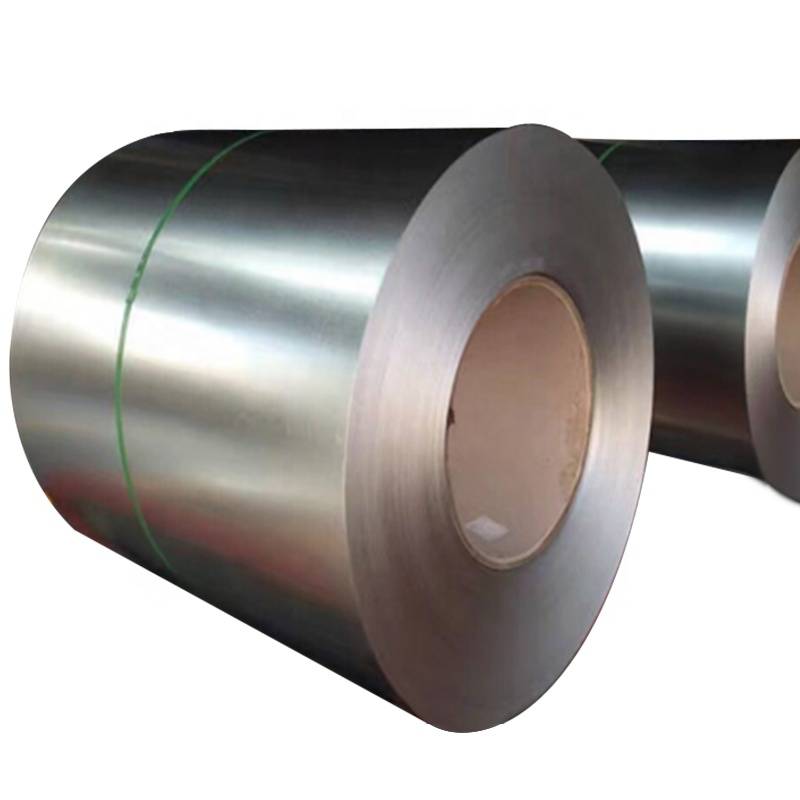

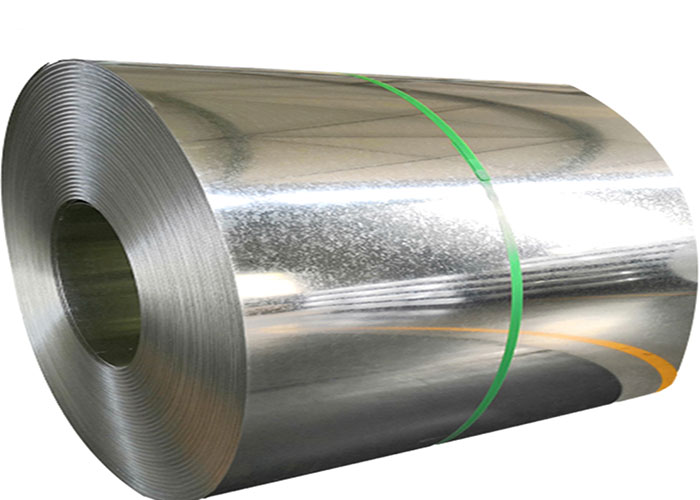

- Galvanized steel coil

- Galvanized steel plate

- Pre-painted Galvanized Steel Coil

- Handox wear resistant steel plate

Galvanized steel is defined as a carbon steel sheet coated with zinc on both sides. There are two main processes used to produce galvanized steel: continuous hot dipping and electro-galvanizing. The hot dipping process consists of passing the steel through a bath of molten zinc, while the electro-galvanizing process consists of the application of zinc through electrolytic disposition. The result is a layer of zinc tightly adhering to the base metal through an iron-zinc bonding layer.

Most important, our hot-dipped galvanized steel coil and sheet service capabilities include slitting,cutting to length, blanking, degreasing and brushing, stretcher leveling and metallurgical support.

| Product Name: | SPCC DC01 Grade cold rolled galvanized steel coil |

| Standard: | ASTM DIN GB JIS |

| Grade: | SPCC |

| Coil weight: | 3-10 ton or according to your request |

| Thickness: | 0.4-2.0mm |

| Width: | 600mm-1500mm |

| Zinc coating: | 40-275 g/m2 |

| Surface | Oiled/unoiled |

| MOQ: | 1 ton per color/ size |

| Supply Ability: | 5000t/month |

| Delivery Time: | Within 15 days after receiving the pre-payment. |

| Export Packing: | Standard Export Seaworthy Package. |

| Payment Terms: | L/C at sight, T/T or Negotiable. |

Application:

Galvanized steel (GI) are mainly used in building, automobiles, metallurgy, electric equipments and more.

● Building – roof, door, window, roller shutter door and suspended skeleton

● Automobiles – vehicle shell, chassis, door, trunk lid, oil tank, and fender

● Metallurgy – steel sash blank and color coated substrate

● Electric equipements – refrigerator base and shell, freezer, and kitchen equipment