- Stainless steel coil

- Stainless steel plate

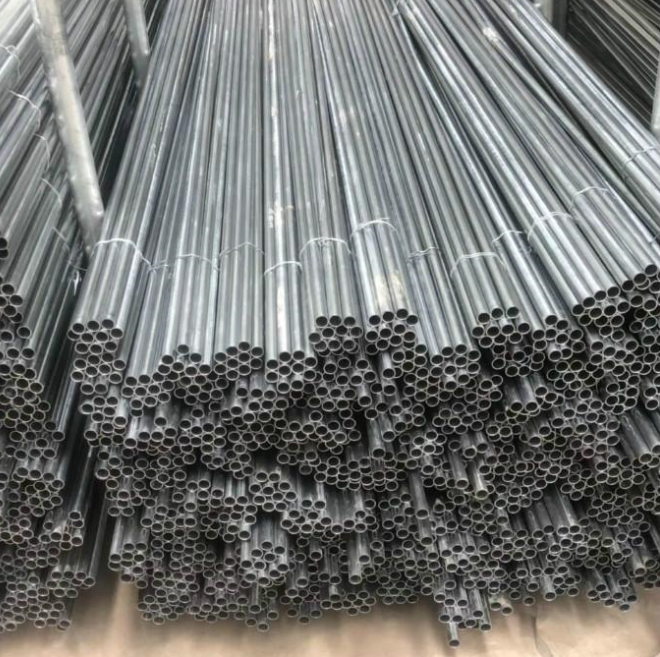

- Stainless steel pipe

- Stainless steel rod

- Stainless steel sections

- Carbon steel coil

- Carbon steel plate

- Carbon steel pipe

- Carbon steel Profile & Section

- Galvanized steel coil

- Galvanized steel plate

- Pre-painted Galvanized Steel Coil

- Handox wear resistant steel plate

410 Stainless Steel Pipe is made up of martensitic steel. Martensitic steels are used when the strength and toughness are needed along with high wear and tear resistance. Their corrosion resistance is lower than the austenitic stainless steels in general. The 410 SS Pipe material has carbon, manganese, silicon, phosphorus, sulfur, chromium and nickel in its material composition. This specific composition provides it with the high wear and tear resistance.We are a manufacturer and supplier of this material grade pipes in different shapes, sizes and dimensions. Any 410 Grade Pipe can be manufactured through cold drawing as 410 Seamless Pipe or through electric resistance weld or through electric fusion weld. The 410 Steel Pipe dimensions vary according to the manufacturing methods as well.

|

Product name |

Stainless Steel Pipe |

|

Material |

304,304L,321,316L,309S,310S,2205,2507,904L,926L,etc. |

|

Outsider Diameter |

6-630mm |

|

Wall Thickness |

0.5-40mm |

|

Surface |

2B, BA, 8K, No. 4, No.1 |

|

Application |

Building materials, kitchen ware, water heater, medical instrument... |

|

Feature |

corrosion resistance, heat resistance |

|

Type |

pipe |

|

Size |

standard size and other size as your requirement support |

Chemical Composition:

| C | Si | Mn | P | S | Cr |

| ≤ % | ≤ % | ≤ % | ≤ % | ≤ % | % |

| 0.15 | 1.0 | 1.0 | 0.035 | 0.03 |

11.5~13.5 |

Characteristics of 410:

| Yield strength (Mpa) | Tensile strength (Mpa) | Elongation (%) | Hardness Hv |

| ≥ 205 | ≥ 440 | ≥ 20 |

≤ 210 |

410 Stainless Steel Pipe properties:

The following are the properties of grade 410 stainless steel pipes offered by Arch City Steel & Alloy:

Corrosion Resistance:

- Good corrosion resistance to atmospheric corrosion, potable water, and to mild corrosive environments

- Its exposure to everyday activities is generally satisfactory when proper cleaning is performed after use

- Good corrosion resistance to low concentrations of mild organic and mineral acids

Welding Characteristics:

- Readily welded by all standard welding methods

- To reduce the risk of cracking, it is suggested to pre-heat the work piece to 350 to 400 oF (177 to 204o C)

- After welding annealing is recommended in order to retain maximum ductility

Heat Treatment:

- The correct hot work range is 2000 to 2200 oF (1093 to 1204 oC)

- Do not work 410 stainless steel pipes below 1650 o F (899 oC)

Applications of 410 Stainless Steel Pipes

410 pipe is used where abrasion and wear resistance is needed, combined with fair resistance to general corrosion and oxidation

- Cutlery

- Steam and gas turbine blades

- Kitchen utensils

- Bolts, nuts, and screws

- Pump and valve parts and shafts

- Mine ladder rugs

- Dental and surgical instruments

- Nozzles

- Hardened steel balls and seats for oil well pumps