- Stainless steel coil

- Stainless steel plate

- Stainless steel pipe

- Stainless steel rod

- Stainless steel sections

- Carbon steel coil

- Carbon steel plate

- Carbon steel pipe

- Carbon steel Profile & Section

- Galvanized steel coil

- Galvanized steel plate

- Pre-painted Galvanized Steel Coil

- Handox wear resistant steel plate

Grade 316 stainless steel plate is the standard molybdenum-bearing grade of stainless steel plate. The molybdenum gives 316 stainless steel plate better overall corrosion resistant properties than grade 304 stainless steel plate. It has particularly higher resistance to pitting and crevice corrosion in chloride environments. 316 stainless steel plate has excellent forming and welding characteristics. It is readily brake or roll formed into a variety of parts for applications in the industrial, architectural, and transportation fields. Grade 316 stainless steel plate also has outstanding welding characteristics. Grade 316L stainless steel plate is the low carbon version of 316 stainless steel plate and is extensively used in heavy gauge welded components.

Product Name

Stainless Steel Sheets/Plates

Thickness

0.3mm-3mm or 3mm-30mm

Width

20mm-1500mm or as required

Length

1500-6000mm or as required

Standard

ASTM/AISI ,AFNOR,BS,UNS,GB

Technique

Cold rolled/Hot rolled

Surface Treatment

2B, 2D, BA, NO.1, NO.4, NO.8, 8K, mirror, chequered, embossed, hairline, sand blast, Brush, etching, Hot rolled plate (HR), Cold rolled sheet (CR), SATIN (Met with Plastic Coated) etc

Thickness Tolerance

±0.01mm~ ±0.25mm

Material

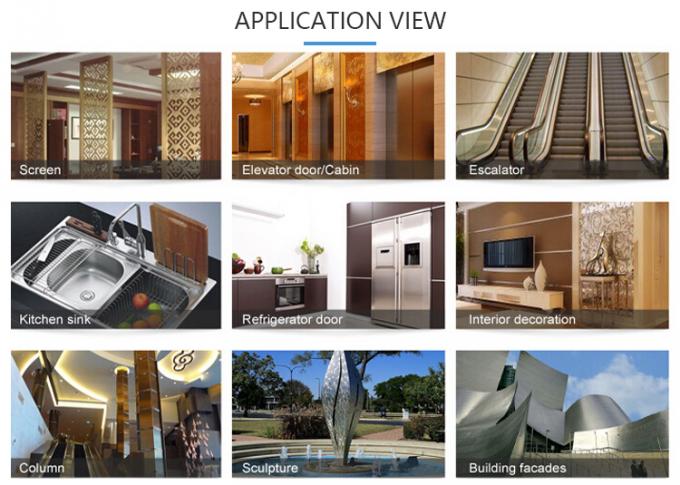

Application

It is mainly used in chemical industry, petroleum, petrochemical and automotive industries.

MOQ

1 ton , We can accept sample order.

Shipment Time

Within 15-20 workdays after receiving deposit or workable L/C

Export Packing

Standard Export Seaworthy Package.Suit for all kinds of transport,or as required

Capacity

250,000 tons/year

316/316L

Chemical Composition:

Weight % (all values are maximum unless a range is otherwise indicated)

| Element | 316 | 316L |

| C | 0.08 | 0.03 |

| Si | 0.75 | 0.75 |

| Mn | 2.0 | 2.0 |

| S | 0.03 | 0.03 |

| P | 0.045 | 0.045 |

| Cr | 16.0 min.-18.0 max. | 16.0 min.-18.0 max. |

| Ni | 10.0 min.-14.0 max. | 10.0 min.-14.0 max. |

Mechanical Properties :

Typical Values at 20°C

| ASTM | |||

| Typical* | Type 316 | Type 316L | |

| 0.2% Offset Yield Strength, ksi | 44 | 30 min. | 25 min. |

| Ultimate Tensile Strength, ksi | 85 | 75 min. | 70 min. |

| Elongation in 2 inches, % | 56 | 40 min. | 40 min. |

| Reduction in Area, % | 69 | — | — |

| Hardness, Rockwell B | 81 | 95 max. | 95 max. |

In most applications Alloy 316/316L has superior corrosion resistance to Alloy 304/304L. Process environments that do not corrode Alloy 304/304L will not attack this grade. One exception, however, is in highly oxidizing acids such as nitric acid where stainless steels containing molybdenum are less resistant. Alloy 316/316L performs well in sulfur containing service such as that encountered in the pulp and paper industry. The alloy can be used in high concentrations at temperatures up to 120°F (38°C).

Alloy 316/316L also has good resistance to pitting in phosphoric and acetic acid. It performs well in boiling 20% phosphoric acid. The alloy can also be used in the food and pharmaceutical process industries where it is utilized to handle hot organic and fatty acids in an effort to minimize product contamination.

Alloy 316/316L performs well in fresh water service even with high levels of chlorides. The alloy has excellent resistance to corrosion in marine environments under atmospheric conditions.

The higher molybdenum content of Alloy 316/316L assures it will have superior pitting resistance to Alloy 304/304L in applications involving chloride solutions, particularly in an oxidizing environment.

In most instances, the corrosion resistance of Alloys 316 and 316L will be roughly equal in most corrosive environments. However, in environments that are sufficiently corrosive to cause intergranular corrosion of welds and heat-affected zones Alloy 316L should be used because of its low carbon content.

Corrosion Resistance