- Stainless steel coil

- Stainless steel plate

- Stainless steel pipe

- Stainless steel rod

- Stainless steel sections

- Carbon steel coil

- Carbon steel plate

- Carbon steel pipe

- Carbon steel Profile & Section

- Galvanized steel coil

- Galvanized steel plate

- Pre-painted Galvanized Steel Coil

- Handox wear resistant steel plate

Alloy 309 (UNS S30900) is an austenitic stainless steel developed for use in high temperature corrosion resistance applications. The alloy resists oxidation up to 1900°F (1038°C) under non-cyclic conditions. Frequent thermal cycling reduces oxidation resistance to approximately 1850°F (1010°C).

309S (UNS S30908) is the low carbon version of the alloy. It is utilized for ease of fabrication. 309H (UNS S30909) is a high carbon modification developed for enhanced creep resistance. It most instances the grain size and carbon content of the plate can meet both the 309S and 309H requirements.Alloy 309 can be easily welded and processed by standard shop fabrication practices.

|

Product Name |

Stainless Steel Sheets/Plates Grade 309 |

|

Thickness |

0.3mm-3mm or 3mm-30mm |

|

Width |

20mm-1500mm or as required |

|

Length |

1500-6000mm or as required |

|

Standard |

ASTM/AISI ,AFNOR,BS,UNS,GB |

|

Technique |

Cold rolled/Hot rolled |

|

Surface Treatment |

2B, 2D, BA, NO.1, NO.4, NO.8, 8K, mirror, chequered, embossed, hairline, sand blast, Brush, etching, Hot rolled plate (HR), Cold rolled sheet (CR), SATIN (Met with Plastic Coated) etc |

|

Thickness Tolerance |

±0.01mm~ ±0.25mm |

|

Material |

309/309S |

|

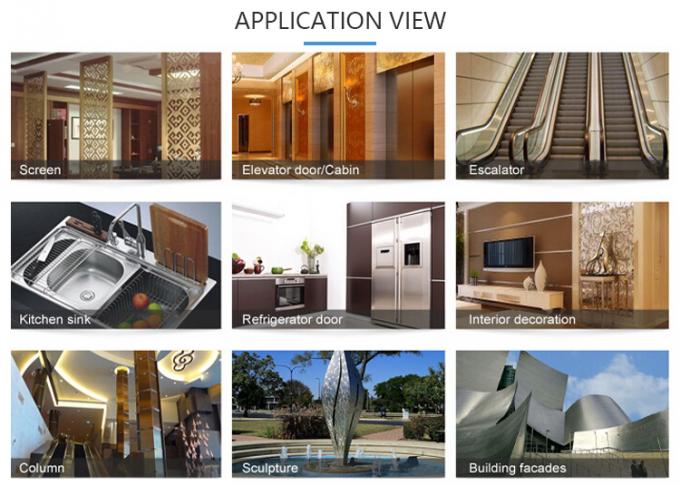

Application |

It is mainly used in chemical industry, petroleum, petrochemical and automotive industries. |

|

MOQ |

1 ton , We can accept sample order. |

|

Shipment Time |

Within 15-20 workdays after receiving deposit or workable L/C |

|

Export Packing |

Standard Export Seaworthy Package.Suit for all kinds of transport,or as required |

|

Capacity |

250,000 tons/year |

Chemical Composition:

Weight % (all values are maximum unless a range is otherwise indicated)

Element

309

309S

309H

C

0.2

0.08

0.04 min.-0.10 max.

Si

0.75

0.75

0.75

Mn

2.0

2.0

2.0

S

0.03

0.03

0.03

P

0.045

0.045

0.045

Cr

22.0 min.-24.0 max.

22.0 min.-24.0 max.

22.0 min.-24.0 max.

Ni

12.0 min.-15.0 max.

12.0 min.-15.0 max.

12.0 min.-15.0 max.

Mechanical Properties :

Typical Values at 20°C

Yield Strength

Ultimate Tensile

Elongation

Hardness

0.2% Offset

Strength

in 2 in.

psi (min.)

(MPa)

psi (min.)

(MPa)

% (min.)

(max.)

45,000

310

85,000

586

50

202 (HBN)

Corrosion Resistance

Wet Corrosion

Alloy 309 is not designed for service in wet corrosive environments. The high carbon content, which is present to enhance creep properties, has a detrimental effect on aqueous corrosion resistance. The alloy is prone to intergranular corrosion after long term exposure at high temperatures. However, due to its high chromium content (23%), Alloy 309 is more corrosion resistant than most heat resistant alloys.

High Temperature Corrosion

Alloy 309 resists high temperature corrosion in most in-service conditions. Operating temperatures are as follows:

Oxidizing conditions (max. sulfur content – 2 g/m3)

1922°F (1050°C) continuous service

2012°F (1100°C) peak temperature

Oxidizing conditions (max. sulfur greater than 2 g/m3)

1742°F (950°C) maximum temperature

Low oxygen atmosphere (max. sulfur content – 2 g/m3)

1832°F (1000°C) maximum temperature

Nitriding or carburizing atmospheres

1562 –1742°F (850 – 950°C) maximum

APPLICATIONS:

Alloys 309 and 309S are used exclusively for their high temperature oxidation resistance, excellent high temperature strength, along with their resistance to creep deformation and environmental attack. Some examples include, but are not limited to:

- Heating elements

- Aircraft and jet engine parts

- Heat exchangers

- Carburizing annealing products

- Sulfite liquor handling equipment

- Kiln liners

- Boiler baffles

- Refinery and chemical processing equipment

- Auto exhaust parts