- Stainless steel coil

- Stainless steel plate

- Stainless steel pipe

- Stainless steel rod

- Stainless steel sections

- Carbon steel coil

- Carbon steel plate

- Carbon steel pipe

- Carbon steel Profile & Section

- Galvanized steel coil

- Galvanized steel plate

- Pre-painted Galvanized Steel Coil

- Handox wear resistant steel plate

No. 1/HRAP

A moderately rough and dull surface, a No. 1 Finish involves rolling stainless steel that has been heated prior to rolling (hot-rolling). This is accomplished by a heat treatment that produces a uniform microstructure (annealing) and ensures that the stainless steel will meet mechanical property requirements. The resulting surface contains a dark non-uniform appearance where surface chromium has been lost, and the expected level of corrosion resistance has been achieved. A No. 1 finish may contain shiny spots were surface imperfections were removed by grinding. It is generally used in industrial applications, such as equipment for elevated temperature service.

No. 2B

A No. 2B finish is the most widely used stainless steel surface finish and is produced very similar to the No. 2D finish. Cold rolled, heat treated, pickled and pinch passed – this is a bright cold rolled finish except that the final light cold rolling pass is done using polished rolls. The result is a more reflective finish that resembles a cloudy mirror. It is especially common in industrial, chemical and food processing applications but also used in some architectural applications that will not be closely examined for uniformity of finish.

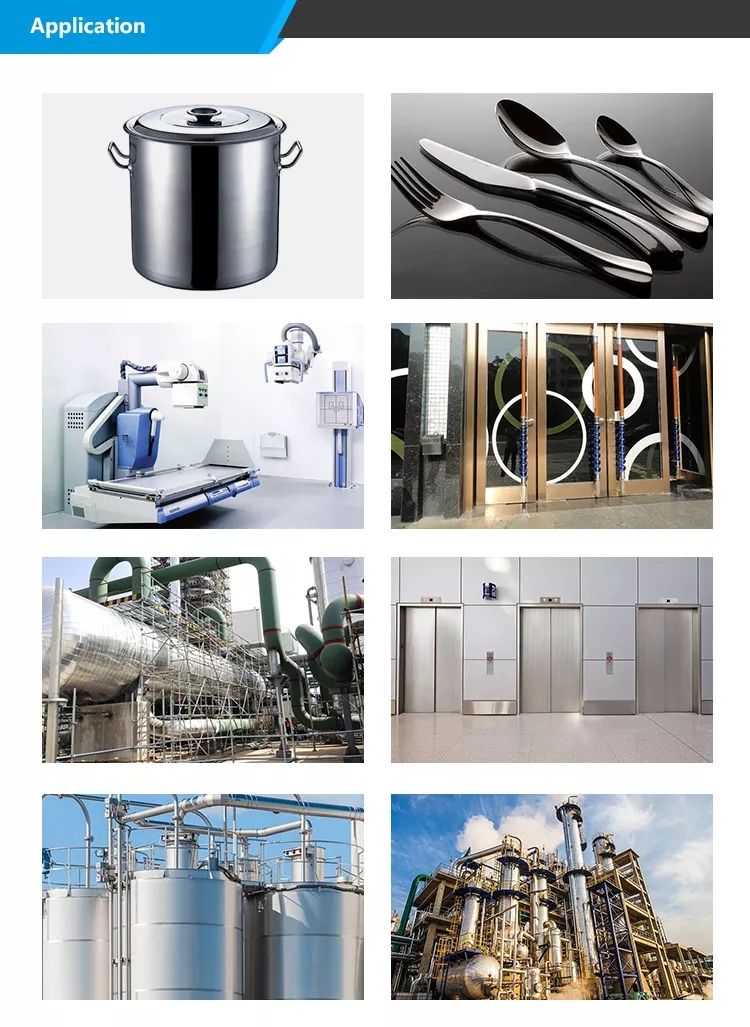

Stainless steel is a versatile stainless steel that is widely used in the production of equipment and parts that require good comprehensive performance (corrosion resistance and molding).In order to maintain the corrosion resistance inherent in stainless steel, stainless steel plate must contain more than 18% chromium and more than 8% nickel content.

Chemical Composition

-

No Next