- Stainless steel coil

- Stainless steel plate

- Stainless steel pipe

- Stainless steel rod

- Stainless steel sections

- Carbon steel coil

- Carbon steel plate

- Carbon steel pipe

- Carbon steel Profile & Section

- Galvanized steel coil

- Galvanized steel plate

- Pre-painted Galvanized Steel Coil

- Handox wear resistant steel plate

Alloy 410 stainless steel plate is the general purpose 12% chromium martensitic stainless steel that can be heat treated to obtain a wide range of mechanical properties. 410 stainless steel plate possesses high strength and hardness coupled with good corrosion resistance. Alloy 410 stainless steel plate is ductile and can be formed. It is magnetic in all conditions.

410 stainless steel materials can readily be welded, it is limited by its hardenability, and it should be pre-heated to reduce the risk of cracking. Post weld heat treatment is not necessarily needed, but recommended to retain required properties, and should be air cooled after annealing.

|

Product Name |

Stainless Steel Sheets/Plates |

|

Thickness |

0.3mm-3mm or 3mm-60mm |

|

Width |

20mm-1500mm or as required |

|

Length |

1500-6000mm or as required |

|

Standard |

ASTM/AISI |

|

Technique |

Cold rolled/Hot rolled |

|

Surface Treatment |

2B, 2D, BA, NO.1, NO.4, NO.8, 8K, mirror, chequered, embossed, hairline, sand blast, Brush, etching, Hot rolled plate (HR), Cold rolled sheet (CR), SATIN (Met with Plastic Coated) etc |

|

Thickness Tolerance |

±0.01mm~ ±0.25mm |

|

Material |

410 |

|

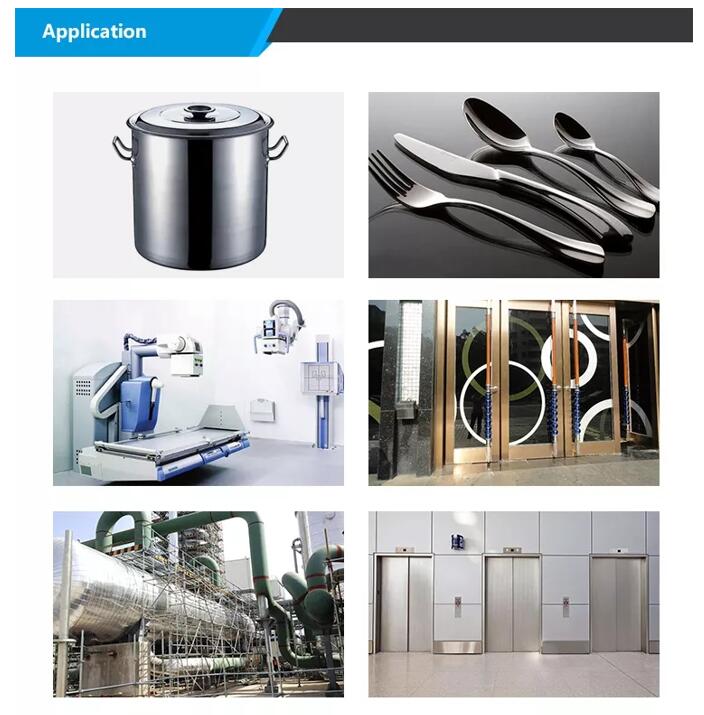

Application |

It is mainly used in chemical industry, petroleum, petrochemical and automotive industries. |

|

MOQ |

1 ton , We can accept sample order. |

|

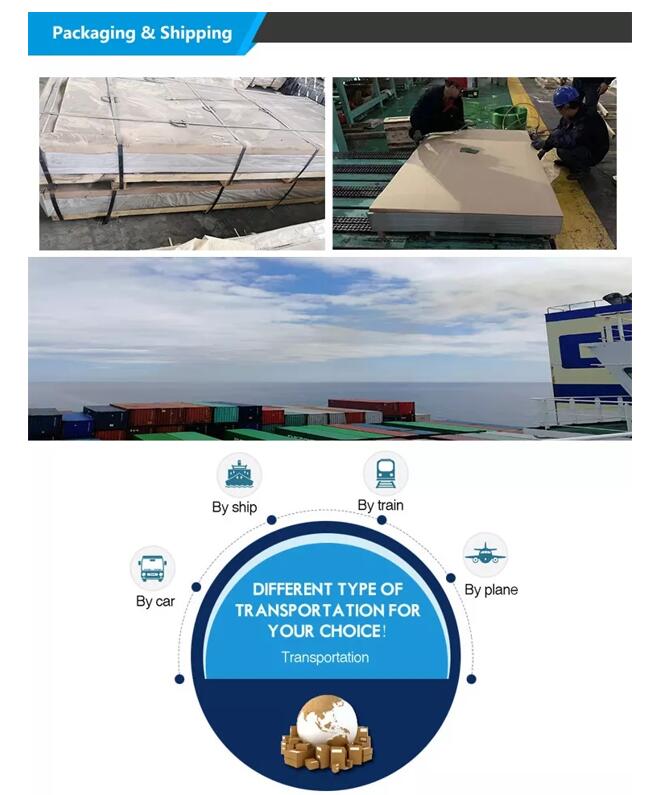

Shipment Time |

Within 15-20 workdays after receiving deposit or workable L/C |

|

Export Packing |

Standard Export Seaworthy Package.Suit for all kinds of transport,or as required |

|

Capacity |

250,000 tons/year |

Chemical Composition:

| C | Si | Mn | P | S | Cr |

| ≤ % | ≤ % | ≤ % | ≤ % | ≤ % | % |

| 0.15 | 1.0 | 1.0 | 0.035 | 0.03 |

11.5~13.5 |

Characteristics of 410

| Yield strength (Mpa) | Tensile strength (Mpa) | Elongation (%) | Hardness Hv |

| ≥ 205 | ≥ 440 | ≥ 20 | ≤ 210 |

Corrosion Resistance

Alloy 410 stainless steel plate is resistant to atmospheric conditions, water and some chemicals. It can be used in environments containing weak or diluted acetic acid, naptha, nitric acid and sulfuric acid. The alloy is also resistant to acids contained in foods.

410 stainless steel plate can also be used in slightly chlorinated and desaereted water. It performs well in oil and gas applications where desaereted and low hydrogen sulfide exist. However, the alloy is prone to chloride attack, particularly in oxidizing conditions.

410 stainless steel plate stainless steel plate operates well in environments requiring moderate corrosion resistance and high mechanical properties.

Oxidation Resistance

Alloy 410 stainless steel plate resists oxidation up to 1292°F (700°C) continuously, and up to 1500°F (816°C) on an intermittent basis.

Applications of 410 stainless steel coils & sheets:

- Aerospace Structures

- Automotive exhausts, manifolds and high temperature engine components

- Medical instruments and devices

- Petro-chemical applications

- Cutlery, kitchen utensils

- Flat springs

- Hand Tools