- Stainless steel coil

- Stainless steel plate

- Stainless steel pipe

- Stainless steel rod

- Stainless steel sections

- Carbon steel coil

- Carbon steel plate

- Carbon steel pipe

- Carbon steel Profile & Section

- Galvanized steel coil

- Galvanized steel plate

- Pre-painted Galvanized Steel Coil

- Handox wear resistant steel plate

Alloy 904L is a superaustenitic stainless steel that is designed for moderate to high corrosion resistance in a wide range of process environments. The combination of high chromium and nickel content, coupled with additions of molybdenum and copper, assure good to excellent corrosion resistance.

With its highly alloyed chemistry — 25% nickel and 4.5% molybdenum, 904L provides good chloride stress corrosion cracking resistance, pitting and general corrosion resistance superior to 316L and 317L molybdenum enhanced stainless steels.

Alloy 904L was originally developed to withstand environments containing dilute sulfuric acid. It also offers good resistance to other inorganic acids such as hot phosphoric acid as well as most organic acids.

Alloy 904L is easily welded and processed by standard shop fabrication practices.

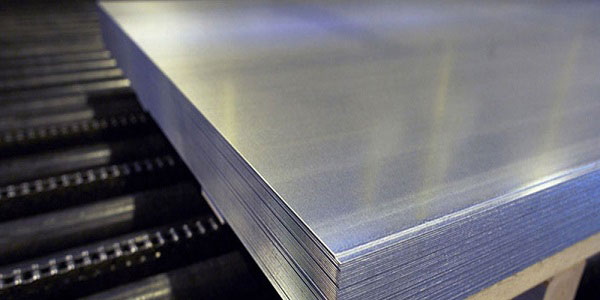

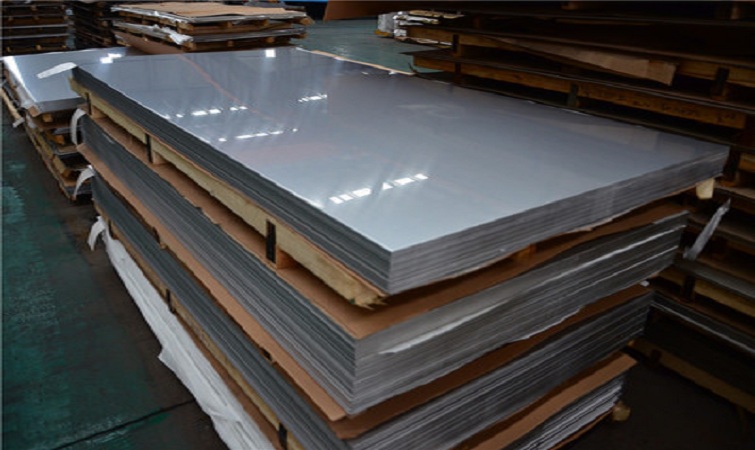

Product Name

Stainless Steel Sheets/Plates

Thickness

0.3mm-3mm or 3mm-50mm

Width

20mm-1500mm or as required

Length

1500-6000mm or as required

Standard

ASTM/AISI

Technique

Cold rolled/Hot rolled

Surface Treatment

2B, 2D, BA, NO.1, NO.4, NO.8, 8K, mirror, chequered, embossed, hairline, sand blast, Brush, etching, Hot rolled plate (HR), Cold rolled sheet (CR), SATIN (Met with Plastic Coated) etc

Thickness Tolerance

±0.01mm~ ±0.25mm

Material

Application

It is mainly used in chemical industry, petroleum, petrochemical and automotive industries.

MOQ

1 ton , We can accept sample order.

Shipment Time

Within 15-20 workdays after receiving deposit or workable L/C

Export Packing

Standard Export Seaworthy Package.Suit for all kinds of transport,or as required

Capacity

250,000 tons/year

904L

Chemical Composition:

Grade

C

Mn

Si

P

S

Cr

Mo

Ni

Cu

904L

min.

-

-

-

-

-

19

4.0

23

1.0

max.

0.02

2.0

1.0

0.045

0.035

23

5.0

28

2.0

Mechanical Properties:

Grade

Tensile Strength (MPa) min

Yield Strength 0.2% Proof (MPa) min

Elongation (% in 50mm) min

Hardness

Rockwell B (HR B)

Brinell (HB)

904L

490

220

36

70-90 typical

150

Applications

- Aerospace – piston engine manifolds

- Chemical Processing

- Expansion Joints

- Food Processing – equipment and storage

- Petroleum Refining – polythionic acid service

- Waste Treatment – thermal oxidizers

Benefits

- Higher creep stress and rupture properties when compared with 304

- Ideal for high temperature service

- Overcomes sensitization and intergranular corrosion concerns

- Can be used in elevated temperature applications for ASME Boiler and Pressure Vessel Code applications

- Excellent mechanical properties